String transport

The structure of the string transport is incredibly simple and extremely efficient.

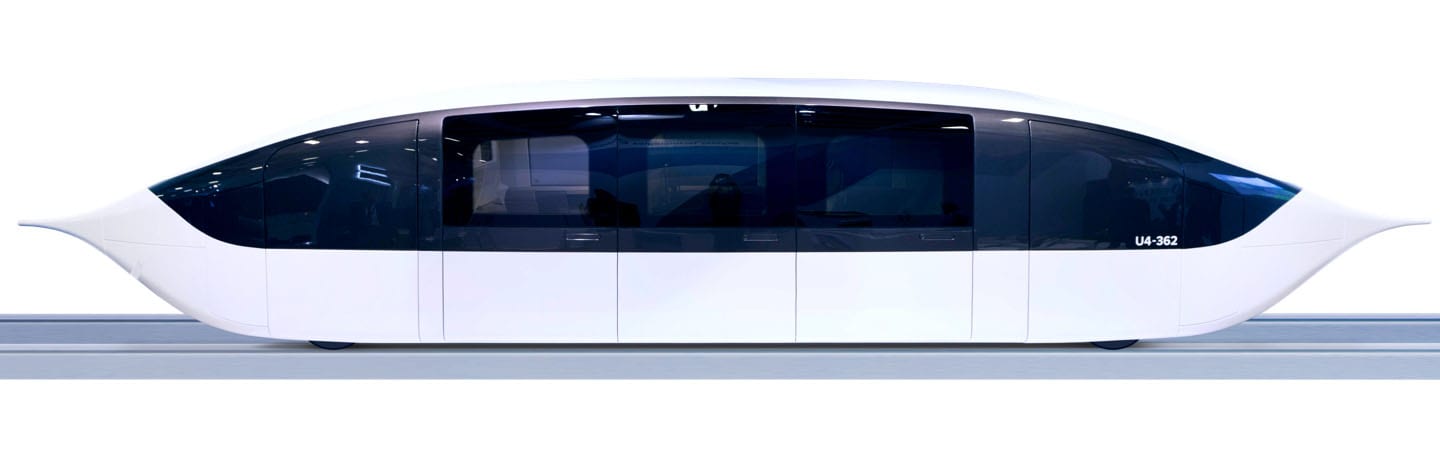

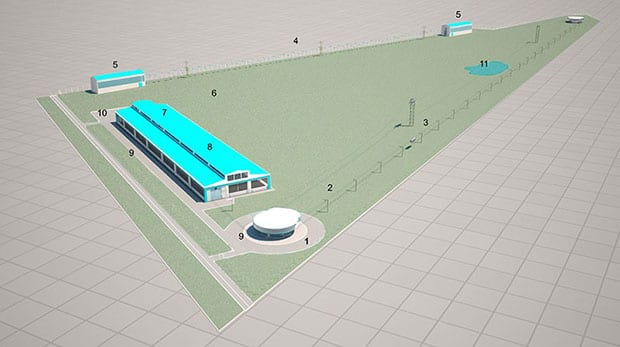

There are steel strings stretched inside the rail, enabling it to bear heavy loads and ensuring high track evenness. As a result, the transport can reach speeds of up to 500 km/h.

String rails are able to place inside any communication networks, creating a fundamentally new approach of interaction between people.

Anchor supports lift the string track above the ground — that makes it possible to exclude intersections with any types of transport and ensure the highest safety indicators.

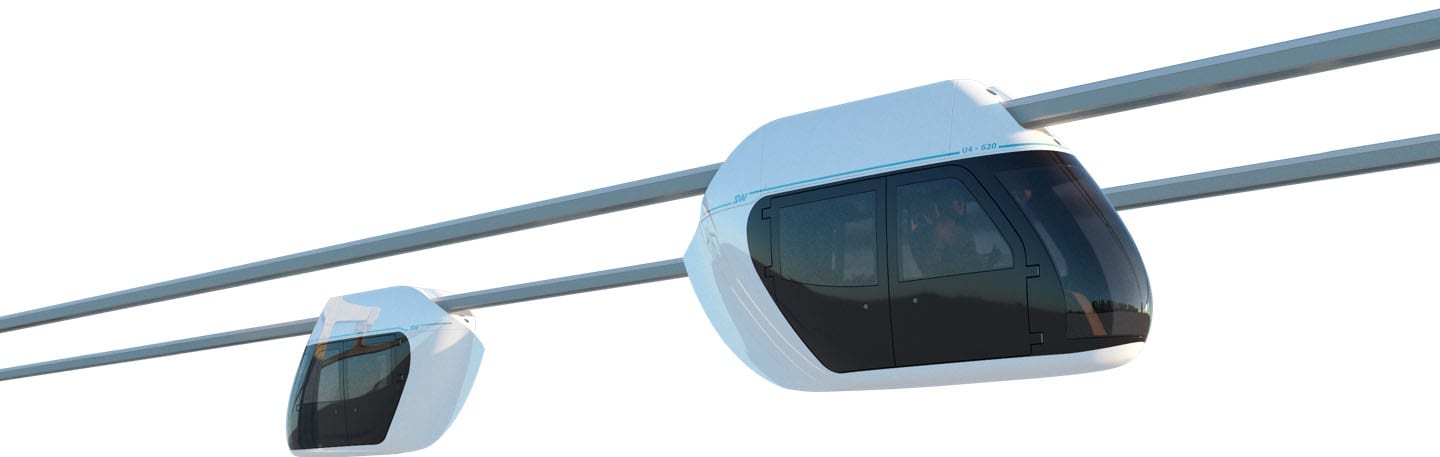

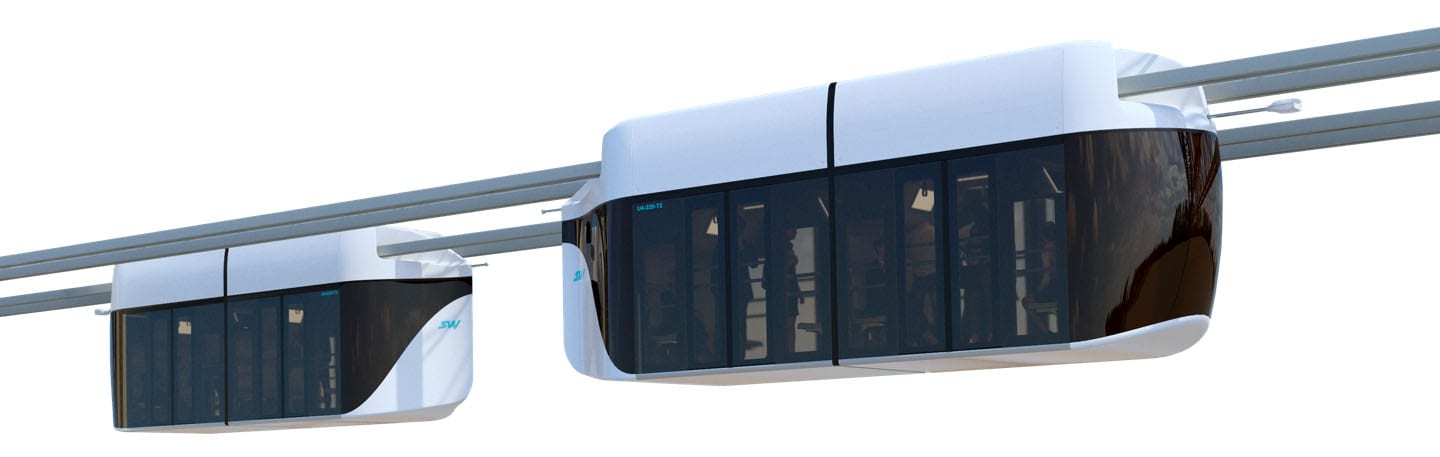

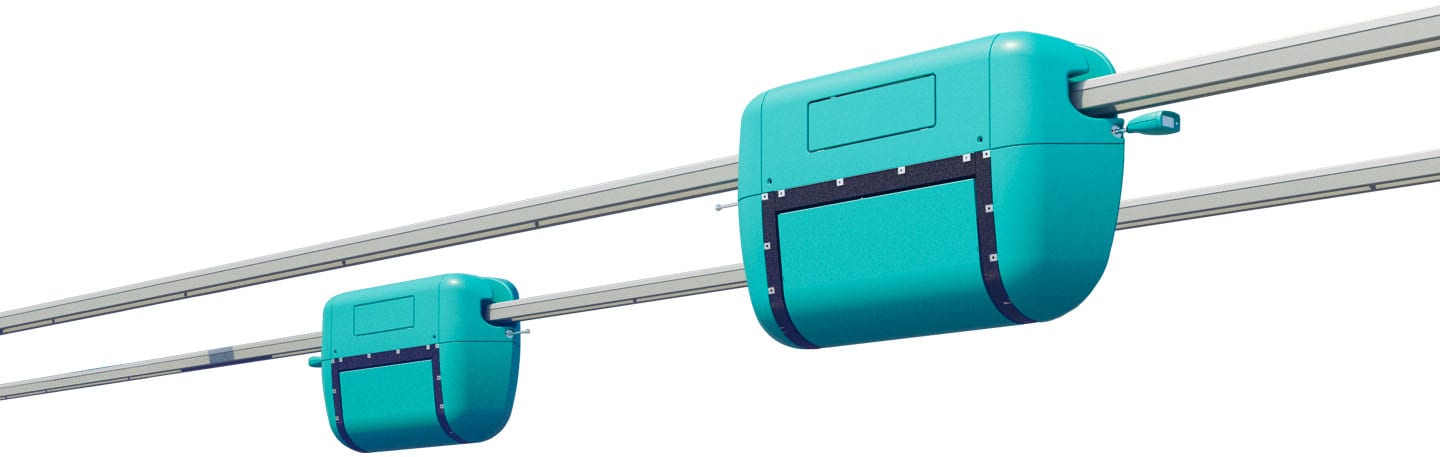

The string transport rolling stock has no analogues. It can be powered by a diesel, turbine, petrol or electric engine.

The string transport is equipped with the unmanned control system, which eliminates the human factor and qualitatively increases the level of safety. Its aerodynamic properties enable it to achieve incredible speeds combined with a comfortable ride.

The string transport infrastructure can be built in any location. Its architectural elements have a large number of variations, making each node visually and functionally unique.

The design of the buildings and interchange stations allows for continuous, non-scheduled traffic. With such a design, passengers will be able to use transport quickly and comfortably, without wasting time on waiting.

>- the track structure is above the ground which increases safety by about 100 times

- the anti-derailment system increases safety by another 10 times

- the automated control system eliminates human factors

- The string transport runs on electricity, therefore, significantly reduces harmful emissions into the atmosphere

- far fewer materials and raw materials are required to produce the entire string transport infrastructure than for any other transport

- String tracks can be built in any terrain with any climate, while preserving the natural ecosystem.

- the cost of building string tracks is up to 20 times lower than the road construction of any other means of transport.

- the fuel costs are up to 6 times lower than fuel costs of other types of transport, respectively, the cost of travel and transportation is much lower

- High-speed string transport can reach speeds of up to 500 km/h - twice as fast as Russia's fastest train “Sapsan”

- Urban string transport can reach speeds of up to 150 km/h - that is twice as fast as buses

- String freight transport can reach speeds of up to 150 km/h

- Author and General Designer of Yunitskiy String Technologies

- Leader of two United Nations projects

- Member of the Cosmonautics Federation of the USSR

- Author of more than 150 inventions

- Author of more than 20 monographs and more than 200 scientific works

- Chairman of the Board of Directors, General Designer of Unitsky String Technologies inc.